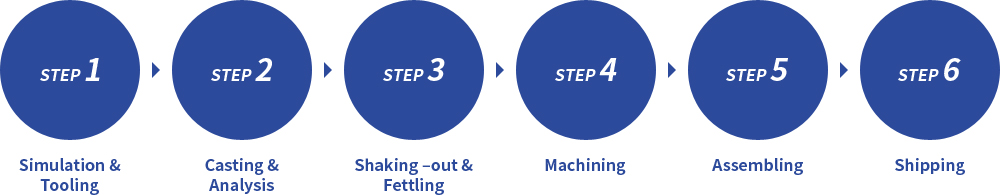

Production Progress

Production Capacity & Line-up

- - Lead Time for Pattern development less than 1 week

- - Lead time for Normal production 4 weeks

- - Casting Capacity is 2.5 tons per pouring, 25 tons per day

- - Batch Processing Production in our facilities

- - Casting Foundry, Shaking-out & Fettling, Passivation & Heat-treatment, Machining Shop and Assembly Shop

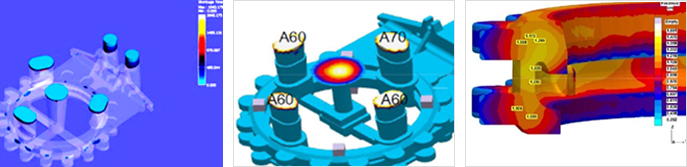

Casting simulation in Laboratory

Casting Simulation

- Solidworks Program- Z-casting Program

Pattern Shop

Pattern Shop Facility

- Pattern built less than a week- Pattern built by NC MC

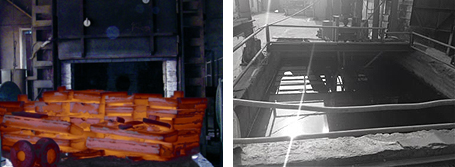

Casting Foundry

Casting capacity

- 25 tons per day- 2.5 tons per pouring

2.5T H-F Induction Furnace

Sand casting molding system

Shaking-out & Fettling

| Shaking-out capacity | Shot Blasting MC |

| - 20 tons per day | - 20 tons X 1 unit |

| - 10 tons X 1 unit | |

| - 5 tons X 1 unit |

Heat-treatment

Heat Treatment capacity

- 30 tons per day- 10 tons per time

10 tons Heat treat furnace

Quenching Bath (6 x 6 x 1.5 m)

Passivation

Passivation capacity

- 20 tons per day- Passivation Bath (2 x 1.5 x 2 m) x 2 units

Machining Shop

| Machining capacity | |||

| - NC Turning MC X 3 unit | - CNC MC X 2 unit | - Conventional Lathe MC X 5 unit | - Milling MC X 4 unit |

| - Radial MC X 5 unit | - Boring MC X 2 unit | - Bending MC X 2 unit |

Assembly Shop

Assembly capacity

- 2” – 60” size of valves- Manual & Control valves assembling capability

Hydraulic & Fuctional Test Shop

Test capacity

- Pneumatic & Hydraulic Test- Functional Test

- Valve size 2” through 60”

- Pressure rate up to CL 600

Pneumatic Test MC X 1 unit

Hydraulic Test MC X 3 unit

Functional Test MC X 1 unit

Inspection Laboratory

Inspection Range

- Chemical inspection120 channel Spectrometer x 1 unit

- Mechanical inspection

Universal Functional Test MC x 1 unit